With the rapid development of my country’s economy, people’s requirements for quality of life are getting higher and higher. Floor heating has been widely used as a comfortable heating method. However, the treatment of floor heating pipe joints has become a key factor affecting the heating effect. This article will introduce the application and advantages of magnetic polishing machine for floor heating pipe joints, and provide an efficient and environmentally friendly solution for the floor heating industry.Magnetic polishing machine solves the metal surface treatment.

1. The importance of floor heating pipe joint treatment-Magnetic polishing machine solves the metal surface treatment

The floor heating system is mainly composed of floor heating pipes, water distributors, insulation layers, etc., among which the quality of floor heating pipe joints is directly related to the safe and stable operation of the entire system. In the process of floor heating installation, pipeline connection is an indispensable link. If the floor heating pipe joints are not handled properly, the following problems will occur:

Water leakage: Water leakage at the joints will lead to a decrease in the heating effect and even affect the normal operation of the entire floor heating system.

Blockage: Dirt, rust and other impurities are easily accumulated at the joints, resulting in pipe blockage and affecting the heating effect.

Corrosion: If the floor heating pipe joints are not handled properly, they are susceptible to corrosion and shorten the service life of the floor heating system.

Therefore, the treatment of floor heating pipe joints becomes a key link in the floor heating installation process.

2. Application of magnetic polishing machine in floor heating pipe joint processing

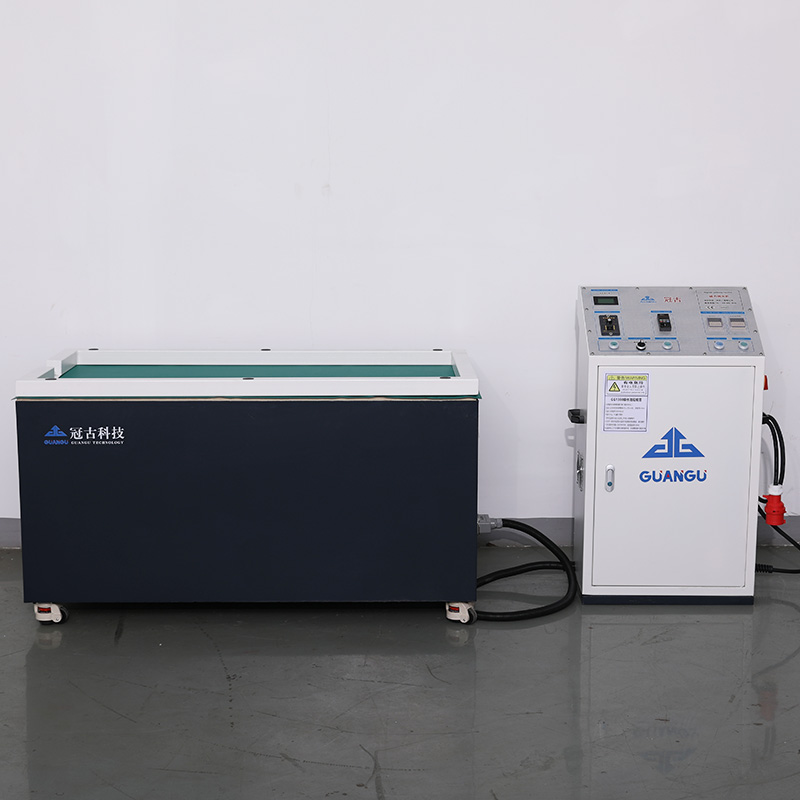

Magnetic polishing machine is an efficient and environmentally friendly surface treatment equipment, suitable for polishing various metal and non-metal materials. In the processing of floor heating pipe joints, magnetic polishing machine has the following advantages:

Fast polishing speed: The magnetic polishing machine uses a high-speed rotating magnetic field to make the polishing medium (various types of grinding steel needles, etc.) collide with the floor heating pipe joint at high speed to achieve rapid polishing.

Good polishing effect: The magnetic polishing machine can select suitable polishing media and polishing liquid according to the floor heating pipe joints of different materials to achieve the ideal polishing effect.

Strong adaptability: The magnetic polishing machine is suitable for floor heating pipe joints of various shapes and specifications, easy to operate, and easy to achieve batch processing.

Environmentally friendly and pollution-free: The magnetic polishing machine uses water-based polishing liquid, no harmful gas emissions, and meets national environmental protection requirements.

3. Advantages of magnetic polishing machine in floor heating pipe joint processing

Improve the quality of the joint: The magnetic polishing machine can remove the oxide layer, rust, burrs, etc. on the surface of the floor heating pipe joint, improve the flatness and finish of the joint, and ensure the sealing performance.

Extend service life: The joints treated by the magnetic polishing machine have a smooth surface and are not easy to corrode, which effectively extends the service life of the floor heating system.

Save costs: The magnetic polishing machine has a high processing efficiency, reducing labor costs and material loss.

Improve corporate image: The use of magnetic polishing machines to process floor heating pipe joints improves product quality and helps to enhance the corporate brand image.

Summary: The application of magnetic polishing machines for floor heating pipe joints in the floor heating industry provides an efficient and environmentally friendly solution for the processing of floor heating pipe joints. With the continuous advancement of technology, magnetic polishing machines will play a greater role in the floor heating industry and help the development of my country’s floor heating industry.

You must be logged in to post a comment.