304 stainless steel parts in the manufacturing process, often produce burrs, sand marks and other surface imperfections, these imperfections not only affect the aesthetics of the parts, but also may have an impact on their performance. How to efficiently and conveniently deburring, has become a problem faced by many engineers and enterprises. Today, we will introduce a magic weapon for you to solve this problem – magnetic polishing machine.

First, 304 stainless steel parts, a must for quality of life

304 stainless steel with its excellent corrosion resistance, wear resistance and aesthetics, has become the preferred material for parts manufacturing in home, automotive, electronics and other fields. However, its burrs, sand marks and other problems generated in the manufacturing process, but many engineers have a headache.

Second, magnetic polishing machine, deburring a new generation of tools

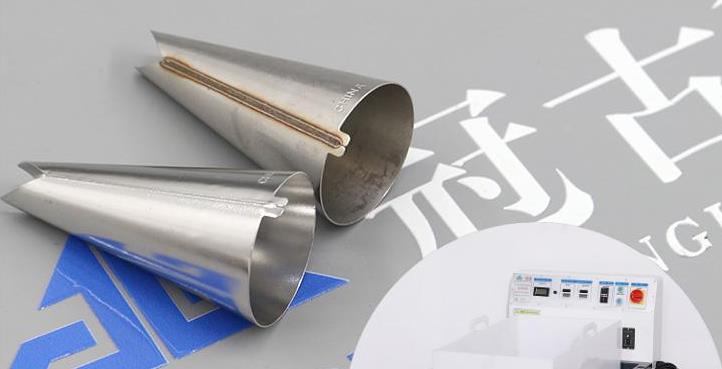

Magnetic polishing machine is a kind of magnetic field adsorption polishing abrasive, the workpiece polishing equipment. Compared with the traditional manual polishing and chemical deburring methods, magnetic polishing machine has the following advantages:

- high efficiency: magnetic polishing machine can simultaneously polish multiple parts in batches, greatly improving the efficiency of deburring.

- stable: magnetic polishing machine through precise control of the polishing abrasive adsorption strength and polishing speed, to ensure the stability of the polishing effect.

- environmental protection: magnetic polishing machine adopts physical polishing method, without the use of chemicals, to avoid environmental pollution.

- Economic: magnetic polishing machine has a low operating cost, can recover the investment in a short time.

Third, magnetic polishing machine in 304 parts deburring application cases

An automotive parts manufacturing enterprises, in the production of 304 stainless steel parts in the process, has been for the deburring problem. After the use of magnetic polishing machine, the enterprise found that the polishing effect is significantly improved, the surface smoothness, brightness have reached the expected requirements, and production efficiency is greatly improved. Enterprises in a short period of time to recover the investment in magnetic polishing machine, saving production costs, enhance product competitiveness.

Fourth, the choice of magnetic polishing machine, so that 304 parts deburring becomes easy!

In this era of the pursuit of quality, 304 stainless steel parts deburring problem no longer gives you a headache. Magnetic polishing machine with its high efficiency, stability, environmental protection, economic characteristics, become the majority of engineers and enterprises trust deburring tool. It allows you to easily deburr 304 parts, improve product quality, and enjoy an efficient, high-quality production life.

Magnetic polishing machine, make 304 parts deburring easy. Choose magnetic polishing machine to make your production more efficient, environmentally friendly, and create greater value for the enterprise. In this era of focusing on quality, let the magnetic polishing machine work with you to create a better future.

You must be logged in to post a comment.